Bringing Asset Performance

into the Data Age

TRUSTED BY GLOBAL LEADERS

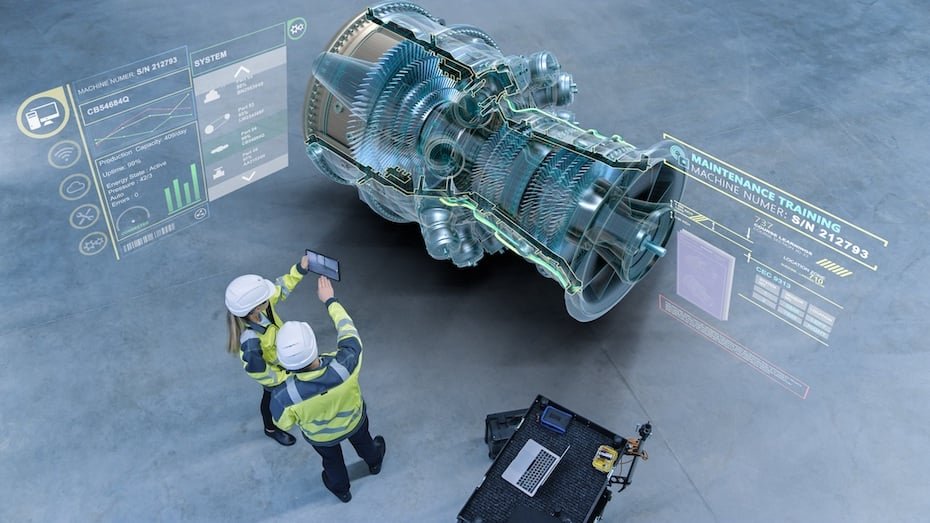

Prescient builds real-time, history-accurate operational digital twins

Accurately predict equipment failures months in advance

52%

Non-Productive Time Reduction

Just-in-time maintenance extends equipment life

40%

Operating Costs Reduction

Achieve 100% digital twin coverage for Precision Drilling

Precision Drilling, a major North American oil & gas drilling company, achieved 100% coverage of its active fleet with 236 mud pump digital twins across 105 rigs. Precision reduced Non-Productive Time by 52% and established itself as an industry leader in equipment quality and operational advantages as ranked by independent research organizations.

WHAT SETS PRESCIENT APART

Prescient’s Transformer-based Asset Life Model encapsulates long-term equipment behavior and predicts failures months in advance

Distributed functional block programming technology enables 20x faster innovation than software coding

Learn more about what makes Prescient’s technology approach unique by downloading our Technology Overview.

Enabling Rapid Data Collection for Bosch Digital Twin Industries

Prescient helps Bosch to automate the data collection and validation process to enable the Bosch team to get high-speed, real-time data in as short as a few days.

Bosch digital twin industries is a leading provider of best-in-class predictive maintenance solutions for asset intensive industries. Having major customers across the globe, it faces the challenge of collecting data from a variety of sensors, machines, and control systems from complex OT/IT environments.

“Prescient knows what it takes to unlock analytics and AI. They are a major enabler for discovering insights from complex, distributed data which can take every product to its next level.”

Amir Kashani, Director AI and Digital Product development - Stanley Black & Decker

Start scaling today.

Request a demo and one of our specialists will reach out to answer your solution-specific questions.